The Vapour permeabilityof Opto Electronics

Vapour permeability plays a crucial role in the use and production of optoelectronic equipment and fibres, particularly in ensuring the longevity, performance, and reliability of these materials and devices. Optoelectronics, which combines optics and electronics (such as LEDs, solar cells, and photodetectors), and fibres used for telecommunications or sensors, are sensitive to environmental factors, including moisture. Here’s how vapor permeability impacts these areas.

1. Moisture Protection and Device Reliability

- Role: In optoelectronic devices, particularly those involving sensitive electronic components like semiconductors, displays, and sensors, moisture ingress can degrade performance, cause corrosion, and result in device failure. Materials with low vapor permeability are essential to act as effective barriers against moisture penetration.

- Importance: By using materials that limit vapor permeability, manufacturers protect sensitive optoelectronic components from moisture, which can affect their electrical properties, cause short circuits, or lead to corrosion. This is especially critical in outdoor applications, such as solar panels, LED street lighting, or fibre-optic cables, where devices are exposed to changing environmental conditions.

2. Packaging Materials for Optoelectronic Devices

- Role: Encapsulation and packaging materials used in optoelectronic equipment, such as OLED displays or photovoltaic cells, need to exhibit very low vapor permeability to protect the internal components from moisture and oxygen. Advanced materials like thin-film encapsulation (TFE) and barrier coatings are often employed to reduce vapor permeability.

- Importance: In devices like OLEDs (Organic Light-Emitting Diodes) or organic solar cells, moisture and oxygen can rapidly degrade the organic layers, reducing their lifespan and efficiency. High-performance barrier coatings with low vapor permeability are essential to prolong the life of these devices by preventing moisture ingress.

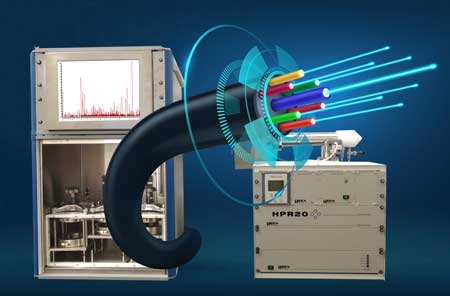

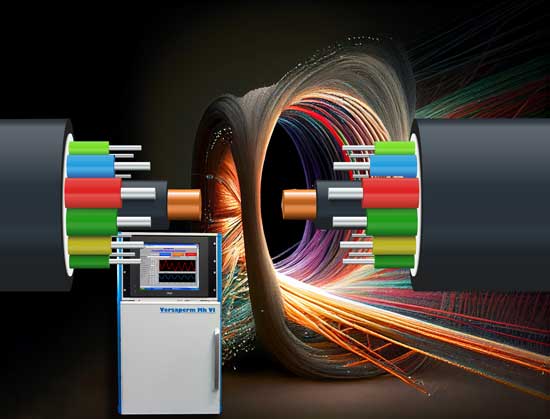

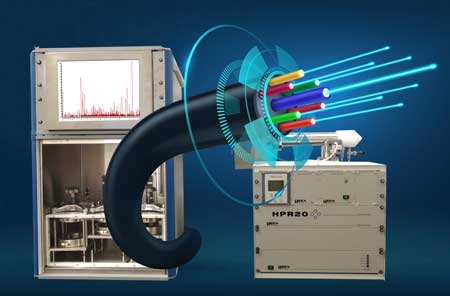

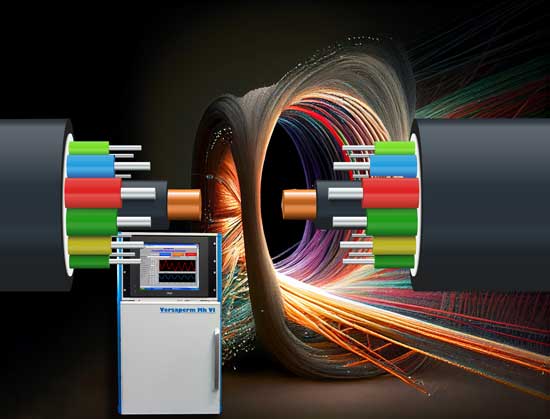

3. Fiber Optics and Telecommunication Cables

- Role: In fibre-optic cables used for telecommunications, vapor permeability must be carefully controlled, particularly in outdoor or underwater applications. Excessive moisture entering the cable’s protective cladding can lead to signal loss, degradation of optical properties, and eventual failure of the fibre.

- Importance: Fiber-optic cables are often deployed in harsh environments where moisture is prevalent. By using materials with low vapor permeability in the cladding or protective sheath of these fibres, moisture ingress can be minimized, ensuring consistent optical performance and longevity of the cable system. This is especially crucial for high-bandwidth communications or undersea cables, where repairs can be expensive and difficult.

4. Environmental Stability of Flexible Optoelectronics

- Role: Flexible optoelectronic devices, including flexible displays, sensors, and wearable electronics, are often exposed to environmental factors, including moisture, heat, and mechanical stress. The materials used in these devices, such as flexible polymers and substrates, need to have controlled vapor permeability to avoid moisture-related damage while maintaining flexibility.

- Importance: In applications like wearable electronics or flexible displays, where comfort and flexibility are key, it is important to manage moisture without compromising the material’s integrity. Some degree of vapor permeability may be beneficial to prevent condensation inside the device, but it must be carefully balanced to avoid moisture ingress that could damage the electronics. This also enhances the device's lifespan and performance under varying environmental conditions.

5. Degradation Prevention in Photovoltaic Systems

- Role: In photovoltaic cells, especially thin-film or organic solar cells, water vapor can penetrate the layers of the solar cell, leading to the degradation of both the organic and inorganic materials. Vapor-permeable materials could lead to delamination, oxidation, or corrosion of critical layers.

- Importance: High-performance barrier layers with low vapor permeability are essential in preventing the degradation of photovoltaic cells. This is particularly relevant in outdoor solar panel installations that must endure extreme weather conditions over many years. Effective moisture barriers ensure that the solar cells maintain their efficiency and performance for longer periods, reducing maintenance costs and increasing energy yield.

6. Protection of Optoelectronic Sensors

- Role: Optoelectronic sensors, such as photodetectors or environmental monitoring sensors, are often exposed to moisture in the form of humidity or condensation. Moisture penetration into these sensors can affect their sensitivity and accuracy.

- Importance: In applications like medical diagnostics, environmental monitoring, or industrial automation, optoelectronic sensors need to maintain high levels of accuracy over time. By utilizing materials with controlled vapor permeability, the sensors can be protected from moisture-induced failures, ensuring reliable performance in a variety of environments. This also reduces the risk of calibration drift caused by moisture exposure.

7. Thermal Management and Efficiency

- Role: In some optoelectronic applications, materials with selective vapor permeability are used to aid in thermal management. For instance, vapor-permeable materials can help dissipate moisture generated by heat or prevent condensation that might form as devices heat up during operation.

- Importance: Allowing excess moisture vapor to escape from the system can prevent the accumulation of condensation inside devices, which could cause thermal stress or short-circuit the electronics. However, too much permeability could lead to environmental moisture ingress, requiring a delicate balance in the material design. This is especially important in high-power optoelectronic devices like lasers or LED modules.

8. Durability in Harsh Environments

8. Durability in Harsh Environments

- Role: Optoelectronic equipment used in aerospace, automotive, or industrial applications must withstand extreme conditions, including high humidity, rain, and even submersion. For these applications, materials with ultra-low vapor permeability are used to encapsulate and protect the electronics from water damage.

- Importance: Optoelectronic devices in harsh environments need materials with very low vapor permeability to function reliably over long periods. For instance, automotive lighting systems using LEDs are exposed to outdoor conditions and must be designed with protective materials to avoid moisture ingress. Similarly, space-based optoelectronics in satellites face extreme conditions where vapor permeability could cause critical failures.

Conclusion

In the realm of optoelectronics and fibres, controlling vapor permeability is essential to ensure device longevity, protect sensitive components, and maintain reliable performance. Whether it’s shielding electronics from moisture damage, preserving the integrity of fiber-optic cables, or enhancing the durability of wearable optoelectronic devices, managing vapor permeability is a fundamental aspect of materials design in these advanced technologies. The right balance between breathability (where needed) and impermeability helps prevent moisture-related degradation, ensuring optimal functionality in demanding environments.

Click here for an artical on Beating permeability problems in Opto Electronics

Click here for a press release

| |

8. Durability in Harsh Environments

8. Durability in Harsh Environments